Industrial machines have held precedence since the Industrial Revolution occurred between 1760 – 1840. The power loom was invented for creating cloth and weaving it together. The cotton gin was invented to get the cotton fibers extracted from cotton seeds faster to expedite clothing production.

Advancements in modern technology have made industrial machines faster and more efficient with higher production output. However, the nation needs specialists to build, operate, and maintain this machinery to keep production going.

Is industrial machinery and components a good career path? We will go over industry information, benefits, skills, and jobs to evaluate the answer.

Table of Contents

- 1 What Is Industrial Machinery?

- 2 Is Industrial Machinery/Components a Good Career Path?

- 3 Benefits of Industrial Machinery/Components As a Career Path

- 4 Skills Needed To Succeed in This Career

- 5 Top Paying Positions in Industrial Machinery/Components

- 6 Final Thoughts on Industrial Machinery as a Good Career

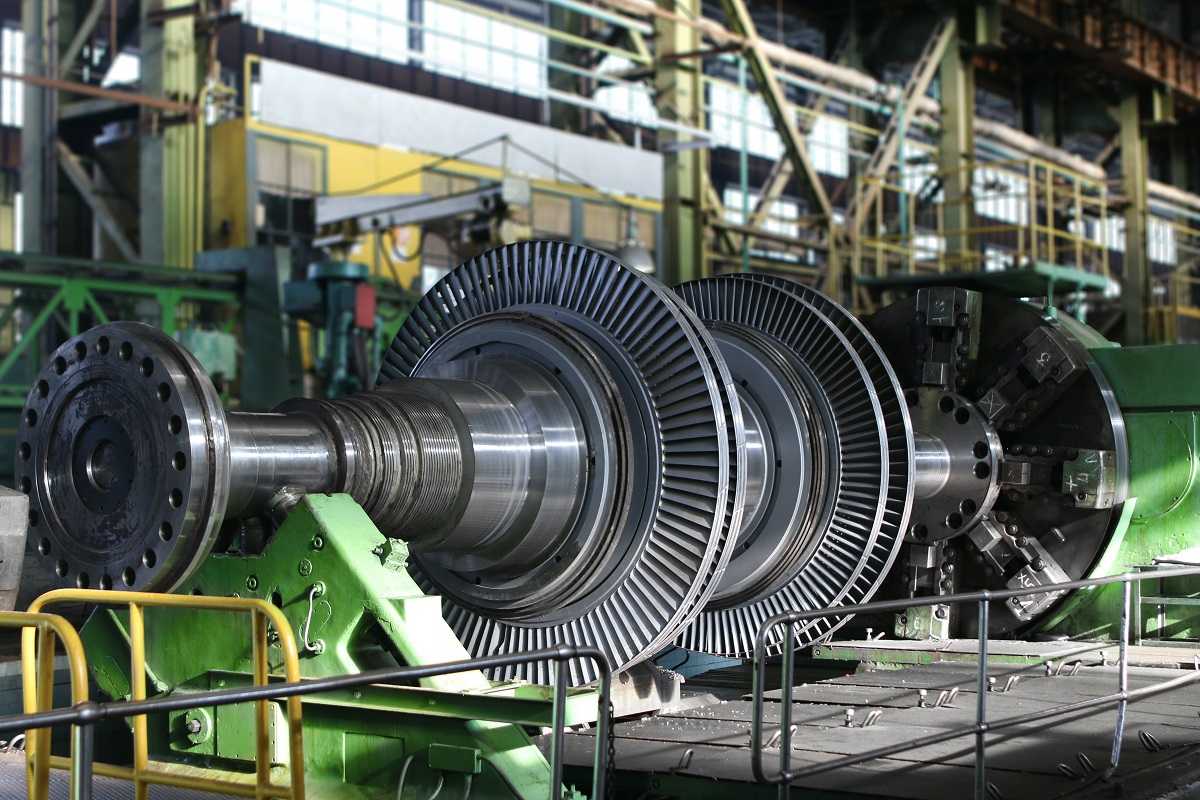

What Is Industrial Machinery?

Industrial machinery is the equipment utilized across multiple industries to manufacture a host of different products. As of 2020, the industrial machinery market was worth $162.9 billion. With a career in industrial machinery, you can work in various industries such as textile, construction, agriculture, mining, food and drinks, and others.

Examples of What Industrial Machinery Produces

Industrial machinery creates many products to fulfill various needs and wants of consumers nationwide. Many items have multiple steps to undergo to reach the final product.

Bulldozers build houses and other buildings throughout a town or city. Liquid fillers, labelers, rinsing machines, and capping machines are the four main devices that package cereal, candy, dried fruit, soda, and other food and drinks.

Textile machinery creates yarn and fiber used for making clothes. Mining machines remove debris to find precious gems and metals used to make jewelry. Fertilizer spreaders and tractors help to plant and cultivate various crops on a farm.

As you can see, the possibilities of what you can help produce are plentiful when you take up a career in industrial machinery.

Components That Help Industrial Machinery To Operate

To have a career in industrial machines, you must also be privy to the machine’s main components. If they are not in operating condition, the machine will not work properly.

Bearings are vital to maintaining the speed of production while maintaining efficiency and precision simultaneously. The three important functions of bearings include:

- Lowering friction during production.

- Keeping the manufactured load supported on the machinery.

- Guiding wheels and shafts to operate accordingly.

Clutch assemblies, hydraulic fittings, bushings, to make a CNC spindle, machining, pulleys, sprockets, and many other components guide an industrial machine to work correctly. Companies must reassure that these components are of high quality so that they do their intended functions and last long-term.

Is Industrial Machinery/Components a Good Career Path?

Yes, working in industrial machines and components is a good career path. For the technical person at heart that loves to know how machinery works, he or she can fulfill their passion.

Keeping the industrial machines operational is the most important for any industry so there is a higher output of the products to increase company sales. The career is not limited to just one industry, so you can find your unique calling to work with machinery and produce almost anything from food to cars to homes and more.

Benefits of Industrial Machinery/Components As a Career Path

The industrial machinery and components career is a valuable trade with multiple niches so you can customize how you work in the industry. You can work in one niche or specialize in multiple to move up to higher-paying positions over time. Here are the benefits of industrial machinery as a career path:

- Health and bonus benefits.

- Health, dental, and vision coverage.

- Sick time leave pay, accidental death insurance, and bonuses even on vacation.

- Disability insurance.

- Work in almost virtually any industry you desire.

- Multiple niches to choose from.

- High-paying positions with great retirement and 401K benefits.

Skills Needed To Succeed in This Career

There are some soft skills and specialized skills that you need to be successful in the industrial machinery and components career. These skills include:

- Mechanical ability.

- Technical mindset.

- Can troubleshoot issues with the machinery.

- Proficient reading skills.

- Commendable hand-eye coordination.

- Base knowledge of how the machinery operates.

- Great attention to detail.

- IQ ability to match your position.

For example, the average IQ of a Mechanical Engineer is 125.5. Automation engineers are like mechanical engineers, except they specialize in automotive aspects of the machinery.

Top Paying Positions in Industrial Machinery/Components

When you decide that you want to pursue industrial machinery and components as your career path, you will want to know the top paying positions available. Here are the three of the highest-paying positions in the industry that will be profitable for yourself and your family in the long run.

Research and Development Engineers

Research and Development Engineers research to advance their companies and develop new solutions in their product lineup. They can help to make new products while making innovations on ones that the company already has out on the market. Revamping the product line and its manufacturing practices will help the company to always advance.

You must obtain a Bachelor’s degree in engineering. Alternatively, you can get a degree in biotechnology or mechanical engineering to enter the field as well. Some companies require at least 3 years of experience in the research and development field to be a Research and Development Engineer.

Salary.com states that Research and Development Engineers make an average salary of $112,486.

Automation Engineers

Automation Engineers assist in streamlining the manufacturing process so that it is easier, faster, and more effective for higher production output. This means configuring machinery to work more efficiently.

To become an automation engineer, you will need to have a Bachelor’s degree in Electrical Engineering or Mechanical Engineering. There are no degrees available with the specialty of automation engineering. Then, obtain a Master’s degree or a certification at a local education institution to get your credentials to be an Automation Engineer.

According to Indeed, Automatic Engineers average $95,324 annually with usually a $5,000 cash bonus each year. The best companies with Automation Engineers jobs in the nation include the United States Air Force, Capital One, and the United States Marine Corps respectively.

Instrumentation Engineer

An Instrumentation Engineer helps to create and maintain factory machinery. They must identify the specifications in which the machinery works so the machine operators know how to get them to properly function.

To become an Instrumentation Engineer, you must obtain a Bachelor’s degree in an engineering field. Once you enter the position, you may have to travel throughout different divisions in the company to maintain the machinery.

Pay scale reports that an Instrumentation Engineer makes an average of $86,244 annually. If you have 20 or more years of experience in the field, you can make upwards of $120,000 annually.

Final Thoughts on Industrial Machinery as a Good Career

There is much opportunity for skills enhancement and money-making potential from working in industrial machinery and components. Find the niche you love, get the education you need, and explore job opportunities in your area to get started.